Understanding material properties creates design opportunities for difficult site conditions. The most important thing to know about material properties is knowing them.

- Intense laboratory testing

- Monthly quality reports by independent inspector

- Daily proof loading of every billet

The emtek product has undergone intensive laboratory testing both during the initial product development stage at the Advanced Structures and Composites Center at the University of Maine and on a continual basis at the Forest Product Laboratory at Mississippi State University. In addition, each billet (the 1′ wide laminated composite element that is bolted together to make the mat) is proof loaded after machining and drilling. During the proof loading process, each billet is loaded to 150% of the allowable design value to ensure that the finished mat will meet the strict design criteria and quality standards. So, if the road is designed for 10,000 pounds, the mat will have been tested to 15,000 pounds to ensure the design will hold up to the expectation on site.

The laboratory testing provides published design properties of the material while routine testing in plant of each billet provides quality assurance.

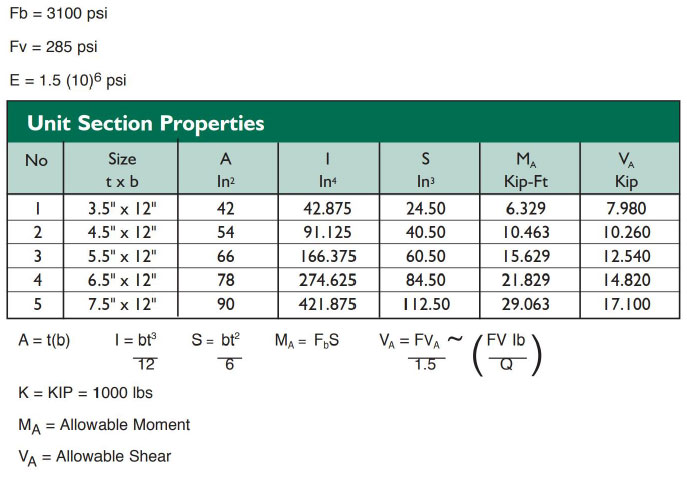

The load tables that are in our Design Guide are based on a one foot wide section of mat. This is because of the variable width mats that we produce (1′-8′). Multiplying the width of the mat by the allowable load will give you the total allowable load when distributed across the mat.